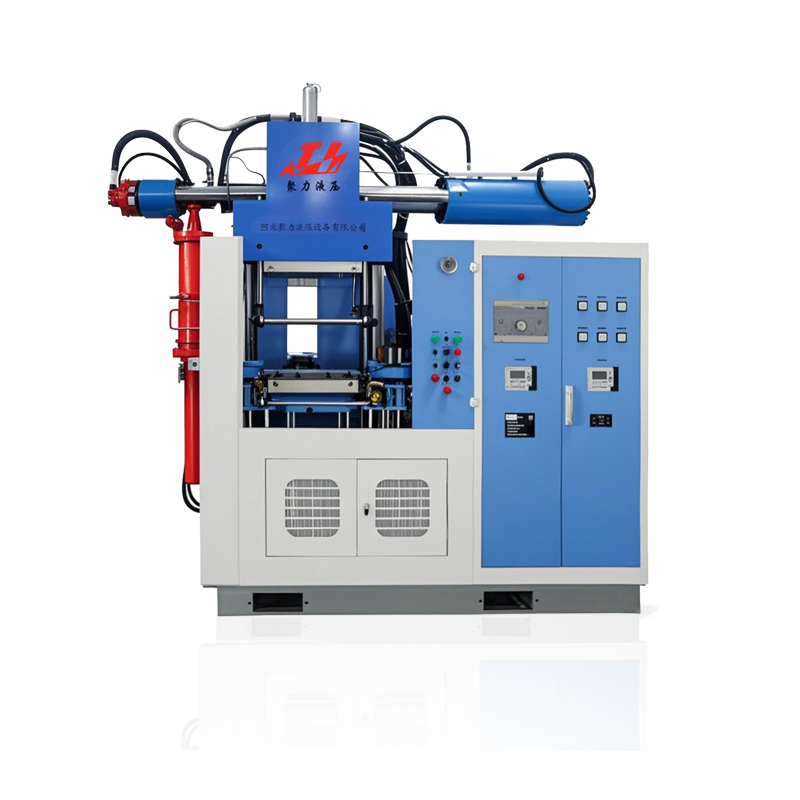

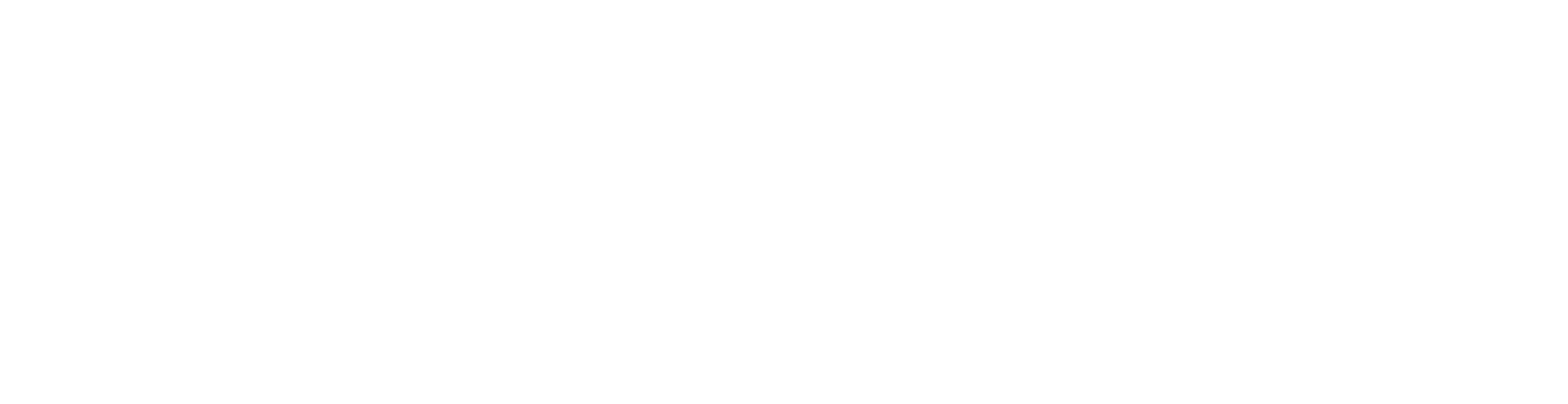

— Injection Molding Machine

| Model | JL-ZSYG200 | JL-ZSNG300A | JL-ZSYG300B | JL-ZSNG400A | JL-ZSYG400B | JL-ZSNG500A | JL-ZSYG500B |

|---|---|---|---|---|---|---|---|

| Injection volume (cc) | 2200 | 3300 | 3300 | 3300 | 6700 | 5000 | 6000 |

| Clamping force (Ton) | 200 | 300 | 300 | 400 | 400 | 500 | 500 |

| Platen size (mm) | 550X600 | 650X700 | 650X700 | 710×750 | 900X900 | 850×900 | 900×900 |

| Injection pressure (MPa) | 170 | 170 | 170 | 170 | 170 | 170 | 170 |

| Opening stroke (mm) | 500 | 600 | 600 | 600 | 600 | 650 | 650 |

| Minimum mold thickness (mm) | 80 | 100 | 100 | 160 | 160 | 200 | 200 |

| Installed capacity (KW) | 31 | 41 | 41 | 45 | 45 | 50 | 50 |

WhatsApp us

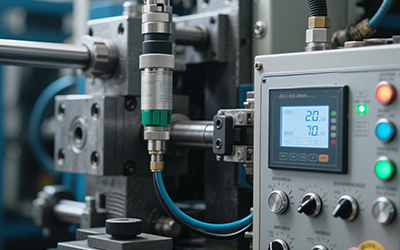

We excel in manufacturing rubber injection molding machines,hydraulic cylinders, and custom rubber-plastic seals. Our premium products, renowned for reliability, are extensively applied in automotive and industrial fields and exported globally. OEM/ODM services are also available.

Sign up to our newsletter